Intelligent automation

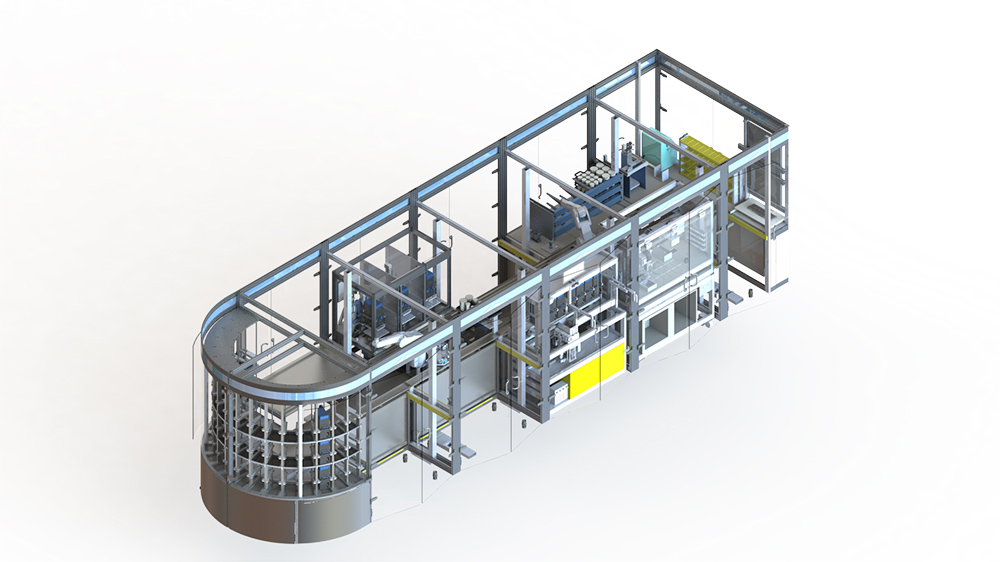

We will exploit existing Chemspeed Technologies robotic platforms in the Materials Innovation Factory in addition to a new £2.5M robotic ‘Formulation Engine’ (Figure 1, built in collaboration with Labman Automation Ltd) and a new £750K Chemspeed Technologies synthetic platform.

The materials design problem is not only computationally challenging: complexity defeats brute force robotic screening, too. For example, Jansen showed that the brute-force experimental search for the high temperature superconductor, YBa2Cu3O7, would require 1012 samples in a 27,000 year research programme (Jansen et al., Angew. Chem., Int. Ed., 2002). ‘Blind’ screening is therefore of limited value, but automation is hugely powerful for more focused, hypothesis-driven searches, where it can accelerate the synthesis and measurement steps in our Materials Design Engine, and hence amplify the interaction between computational and experimental materials design.

This substantial investment in automation robotics puts this centre at the fore front for automation synthesis and formulation within an academic institute. In this Centre, automation is about going broader, as well as faster: for example, to access libraries of 10’s to 1000’s of new materials and property measurements to firmly validate new computer science prediction methods developed.

We will overcome current limitations in automated platforms by producing new methods that work more powerfully within our Materials Design Engine. We will use state-of-the-art, novel algorithms created by our computer scientists and robotics control technologies developed by engineers in our team to enable closed-loop automation and the directed, experimental evolution of function.

Figure 1: Formulation Engine. The Formulation engine will be a state-of- the-art multi user platform that will increase the speed and breadth which formulation science can screen hypothesis driven searches. Operational 2018/19.