Case Study: New Generation Coatings with Intrinsic Antimicrobial Action

A University of Liverpool led project, in partnership with Gencoa Ltd, focused on development on anti-microbial technology using magnetron sputtering technology. This collaborative project, funded by an NBIC proof of concept grant, enabled a new generation of coatings to be created.

Project Summaries

Both projects address a clear unmet need in the current pandemic relating to transmission of SARS-CoV-2 (Covid-19) via the touching of contaminated surfaces in areas such as hospitals, train stations, restaurants and shops. The virus has proven to be particularly resilient, remaining active on plastic and glass surfaces for several days, which poses a significant barrier to resuming public services, reopening hospitality and welcoming workers back to their offices.

Results

Analysis provided by the OPIHAS team at Liverpool included X-ray Photoelectron Spectroscopy (XPS) data on the relative concentrations of the elements present in the near surface region, and the local chemical environments/states of the elements in different coatings. The team also provided Atomic Force Microscopy (AFM) data, enabling the surface topography of the coatings to be imaged, as well as surface bioassays which revealed that specific coatings possessed high anti-bacterial performance.

The coatings methodology and know-how developed during the project formed the basis of two Innovate UK projects submitted by Gencoa, Liverpool and other partners, to develop anti-bacterial and anti-viral coatings for high touch surfaces, expanding Gencoa’s portfolio of products.

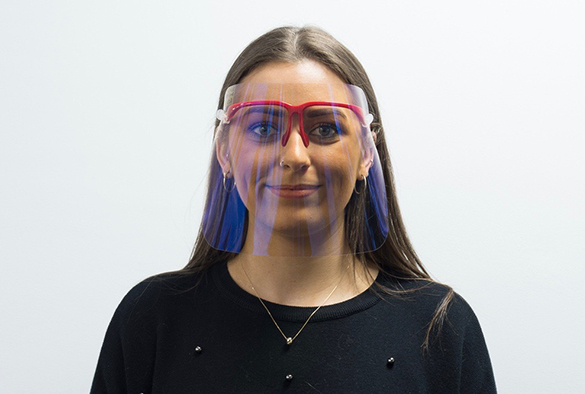

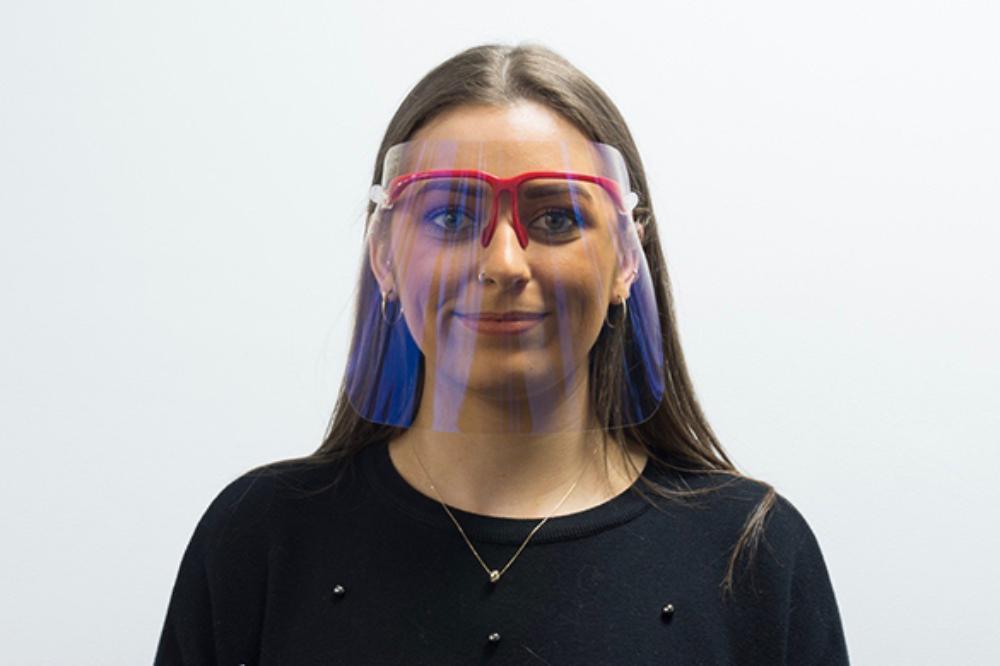

Reusable face visor with anti-viral coatings and high optical performance.

Reusable face visor with anti-viral coatings and high optical performance.

Both applications were successful, with a combined total grant value of ~£500K, and production work on both projects has commenced. Two main applications have been targeted: first, anti-viral coatings to create reusable face visors and goggles with high optical performance; and second a transparent anti-viral touch screen coating for ticket machines used widely in public transport and healthcare.

Dr Monaghan, MD of Gencoa, said, “The success of our grant applications with the University of Liverpool and other partners is the springboard we needed to provide the scientific information of how these surfaces quickly kill viruses and bacteria. We aim to apply this technology around the world in consumer and healthcare settings to help fight infections that are a result of cross-contamination from hand contact with surfaces”.

The combination of advanced coating technology created by Gencoa, with advanced characterisation techniques used by Liverpool, enable differences in antimicrobial performance to be correlated to fabrication conditions and the resultant surface chemistry and topography. This new technology mitigates the potential of the virus to spread from surfaces that people come into regular contact with and show great societal benefits in terms of saving lives and the economy.

Professor Raval, Director of the Open Innovation Hub for Antimicrobial Surfaces said,

“Anti-viral surfaces are at the frontline of Covid-19 control and new surface-based technologies have the potential to break and contain chains of transmission. This project creates an excellent opportunity to translate our state-of-the-art surface science research into UK’s innovation pipeline and help our l SME companies to create new products that will enable key sectors in the UK to open up safely”.