Degraded Handling Qualities

Any handling qualities degradations caused by failure of flight control system components must be assessed early in the design stages to establish severity levels and hence reliability requirements via a Failure Hazard Analysis (FHA), where the pilot must be able to maintain adequate control of the vehicle following a failure. The Flight Science and Technology Research Group at the University of Liverpool is responsible for this investigation, assessing the effect of three failure types on handling qualities:

-

Loss of function – A loss is a frozen value or a default status (the control surface does not respond to the corresponding control input)

-

Malfunction – The control surface deflection is not frozen as in a Loss, but does not move consistently with the input (hard-over, slow-over or oscillations).

-

Degradation of function – The function is still working but with degraded performance (low voltage power supply or reduced hydraulic pressure).

The next step is to consider the affect of the failure and classify the failure probability in terms of flying hours where for example, if a failure is to be classified as minor, it is to be designed such that the probability that the failure will occur is less than once every 1000 flying hours, whereas if a failure is classified as ‘catastrophic', it must be designed such that the probability of occurrence is less than once every billion flying hours.

In order to fully complete the failure hazard analysis study, each type of failure must be considered for each control function in all three modes. However it is clear that certain failures are less severe than others. For example, a rudder malfunction in aeroplane mode is catastrophic but it is not crucial to determine the effect of degraded rudder performance in helicopter mode (except to the extent that conversion to aeroplane mode is then not permissible).

Failure Example:

Effect of Actuator Degradation on Helicopter Mode Yaw HQs

A failure in the hydraulic system will result in a reduced hydraulic pressure being supplied to the actuator, degrading its performance. All degraded modes have to be classified as having no worse than a major effect, therefore in the event of a failure, the tilt-rotor must still be operational, albeit with poorer handling qualities. As a result, it is essential to determine the reduced actuation rate that confers no worse than Level 2 handling qualities in the event of a failure.

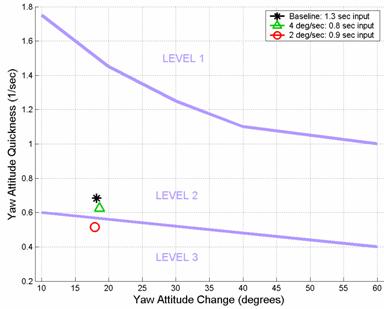

An initial handling qualities assessment can be made offline using the ADS-33 attitude quickness criteria. The yaw attitude quickness example shown in Figure 1 demonstrates the baseline Flightlab XV-15 model as a black star and that as the actuation rate decreases, the attitude quickness also decreases. The minimum actuation rate which confirms Level 2 handling qualities is seen to lie between 2 & 4 degrees/second.

|

|

|

Figure 1 Yaw Attitude Quickness |

To determine the minimum tolerable actuation rate, which allows safe un-impeded flight, a series of piloted simulation trials were conducted at the University of Liverpools Flight Simulation Laboratory, using the Flightlab XV-15 research tilt-rotor aircraft simulation model. The pilots were required to fly a range of primarily single axis Mission Task Elements (MTEs), which were specifically devised to assess the handling qualities of each axis in each mode. At the end of each task, the pilots completed an in-cockpit pilot questionnaire. This not only provided an insight into the vehicle response and limits, but also aided the pilot in returning an HQR using the Cooper-Harper handling qualities rating scale and a PIO (Pilot Induced Oscillation) rating (from the PIO rating scale). The actuation rate was decreased and the process repeated until the Level 2/3 handling qualities boundary was determined.

The Hover-Turn task shown in Figure 2 was used in the simulation trials to assess degraded yaw performance in helicopter mode. The task was to complete a 90 degree turn to the left (between designated start and finishing points), in a specified time, maintaining a reference height, When the turn is finished, a 5 second atabilisation phase must also be completed.

|

|

|

Figure 2 Hover-Turn MTE |

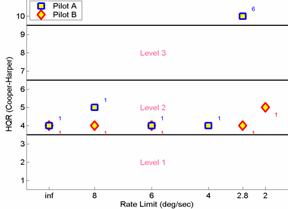

Two pilots flew the task and the HQRs recorded are plotted in Figure 3. The plot shows that neither pilot experienced any adverse handing qualities issues, even when an actuation rate of 4 degrees/second was applied. When this was further decreased, Pilot B still reported Level 2 handling qualities, however Pilot A encountered a severe yaw PIO which resulted in a loss of control, where he returned an HQR 10 and PIO 6 (HQR 10 is the worst handling qualities rating and PIO 6 is the worst PIO rating). Therefore the minimum tolerable actuation rate for the yaw axis in helicopter mode is 4 degrees/second. Clip 1 shows this case, where the only way the pilot could regain control of the CTR, was not to apply any more pedal inputs and let the PIO damp out.

|

|

|

Figure 3 HQ & PIO Ratings |

|

|

|

Clip 1 Hover-Turn – Loss of Control |