A Novel Manufacturing Process for Glass THGEMs

The ARIADNE group has innovated a novel manufacturing process for glass THGEMs overcoming many limitations of the current state-of-the-art, providing a versatile device for a wide range of applications including in medical imaging, biotechnology, material analysis, radiation therapy dosimetry, radiation detection monitoring and astrophysics.

Thick Gaseous Electron Multipliers (THGEMs) are a type of gaseous ionization detector developed at CERN. The effectiveness of THGEMs has resulted in their widespread use within the contemporary field of time projection chamber (TPC) technologies, where TPCs are now integral within the neutrino and dark matter sectors.

Despite the many attractive features of THGEMs, there are limitations in terms of their design and manufacture such as sagging at larger scales, thickness non-uniformity, susceptibility to carbonisation due to discharges, variability in hole sizes and non-radiopurity.

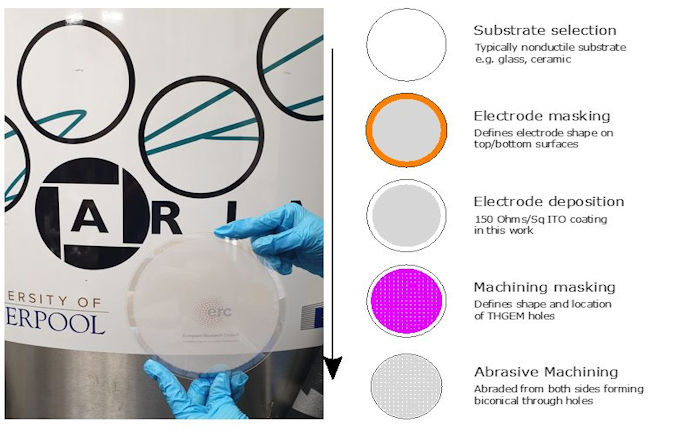

The new glass THGEMs developed at Liverpool address all of the above challenges by allowing the creation of a GEM out of any type of glass material or non-ductile substrate. Our new masked abrasive machining process allows for unprecedented customisation of glass THGEMs. Importantly this is a very scalable technology which the ARIADNE team is already scaling up to a 53 x 53 cm x 1mm glass GEM for operation within the ARIADNE detector and for operation at the CERN Neutrino platform in the New Year for the imaging of a 2 x 2 m large-scale Neutrino detector prototype.

This innovation has been supported by the ERC ARIADNE starting grant and STFC IAA funding, and has been brought to fruition by the talented and strong ARIADNE team led by Dr Kostas Mavrokoridis.

The manufacturing process is now patent pending, and more information can be found in our recent publication: