|

K2 is

a

motor-driven star tracker that I designed and built to

allow

photographs of the

night sky to be taken without the photographs showing

star trails due

to the rotation of the Earth. I wanted to be able to

take the star

tracker on holiday to Kenya (on the equator) and

photograph the skies

there that are unaffected by light pollution.

|

||

So the star tracker

had

to be:

|

In practice,

this means:

|

|

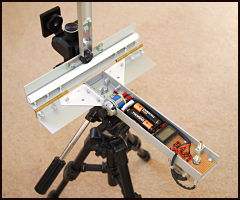

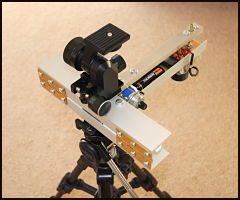

ConstructionAs this was my second star tracker (I built my first one when I was a student at college) I called it K2. I decided to construct K2 from lengths of L-section and U-section aluminium bolted together as this is very strong and very light. The sections make two 'T' shapes, the static base T and the moving top T. The pivot is provided by two brass hinges that connect the two T's together, positioned at the ends of the top bars of the T's. When operating the two T's are pushed apart by a bolt driven at 1 rpm by a small motor and gearbox. The design is optimised for low latitudes (within 20° of the equator), but will also work in the UK (latitude 52°) provided that the camera and lens are not so heavy that they put the whole system out of balance. |

||

|

The M6

bolt

has a 1 mm pitch and is positioned 230 mm from the

hinge axis. A nut

sits on the bolt and is driven upwards as the bolt

rotates (the nut cannot rotate as it is

constrained within the U-section arm that forms the

length of the top

T). Driving the bolt at 1 rpm forces the top T

to rotate at approximately 1/230 of a radian per

minute, or one

revolution per day, to counteract the rotation of the

Earth. The design

is much more accurate than a conventional tangent

drive and much

simpler than a double-arm drive. The reason for the

high accuracy is

explained, with technobabble, here.

|

||

|

||

| In

practise,

the tracking accuracy of K2 is determined by the degree

of alignment

between the hinge axis and the Earth's axis. A polar

scope, used in

some commercial star trackers, is useless if Polaris is

on the horizon.

An alternative method of alignment is to use an

inclinometer and a

compass to set the altitude and azimuth, respectively. A

digital

inclinometer is accurate to 0.1°, but even a

digital compass is only accurate to about 1°

and you have to know the offset between magnetic North

and true North

for your location. Inaccurate polar alignment is the

biggest factor

that affects the overall

tracking accuracy of K2 and I am thinking about ways to

improve it. |

||

|

|

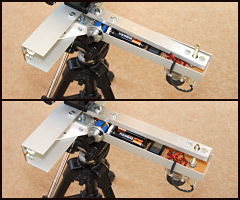

The

image on the left shows K2 at the start (top) and end

(bottom) of a

15-minute run. The motor has turned the bolt 15

revolutions, pushing the nut 15 mm upwards along the

bolt and rotating

the top T by about 4° from its starting

position. At this point the top T can be lifted

off the nut and the nut spun back down the bolt by

hand, ready to start

another 15-minute run.

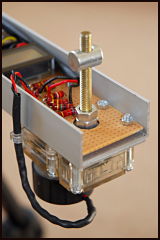

Note that the direction of the bolt moves slightly as the top T moves relative to the base T. The nut moving on the bolt is cylindrical (see close-up image below right) and so the contact point on the underside of the top T 'rolls' over the cylinder. Small strips of teflon on the underside of the top T ensure that the contact between the nut and top T is smooth. |

|

| The

layout

of the components inside the base T is shown in the close-up image above

right. The

resistors are

arranged in two sets. One set is a

potential divider to drop the 3 V supplied by the two AA

batteries down

to the 2.3 V that is needed to drive the motor at 1 rpm

(3 V drives it

at 1.3 rpm). The second set is used to drop either (i)

the voltage

supplied by the batteries or (ii) the voltage across the

motor down to

the appropriate value for display on the LCD voltmeter.

As the

voltmeter is set to read a maximum of 1.999 V (for

maximum resolution)

the battery voltage is divided by 2 and so displays 1.5

V when the

batteries are fresh. The voltage across the motor is

divided by 2.3 so

that the voltmeter reads 1 V when the motor has 2.3 V

across it (and is

rotating at 1 rpm). Thus, the voltmeter effectively

reads rpm. |

Cylindrical

nut

on drive bolt

|

|

|

|

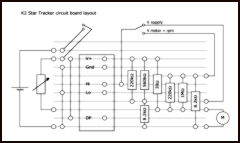

The

layout of

the components inside the base T is shown in the circuit

diagram on the left.

The potentiometer is in parallel with one of the

resistors in the

potential divider that drops the battery supply

voltage down from 3 V

to 2.3 V. This allows the voltage across the motor,

and hence the speed

of the drive, to be adjusted to compensate for the

slow drop in voltage

of the batteries as they gradually run down. When

starting a

photography session, the potentiometer is adjusted

until the voltmeter,

set to read the voltage across the motor (divided by

2.3), reads 1.000

rpm. Over a 15-minute period, the battery voltage will

hardly change at

all, but it can be checked at the end of each

15-minute session when

the top T is lifted to spin the nut back to its

starting position. The

voltage supplied by a battery changes with

temperature, so it's worth

keeping an eye

on it over the course of a night as the temperature

drops.

As K2 was built with hand tools, I could not guarantee that the dimensions were exactly as per theoretical design. This is not a problem. For instance, if when constructed it turns out that the distance from the drive bolt to the hinge axis is 231 mm, rather than 230 mm, then the motor can be set to drive at 231/230 = 1.004 rpm. |

|