Engineers develop new method to recreate fibre-waviness defects in lab

Published on

A new technique developed by Liverpool engineers could improve how aircraft are manufactured leading to lighter aircraft and lower emissions.

Researchers at the University of Liverpool developed a new method to recreate fibre-waviness defects in composite materials within a laboratory environment.

Modern aircraft – including the new Airbus A350 and Boeing 787 - are primarily made using composite materials for structural components, usually plastics reinforced by fibres, which reduces the weight of the aircraft and increases fuel efficiency.

Composites materials are more sensitive to defects than metals and aircraft manufacturers often make new aircraft structures heavier than is otherwise necessary, to account for the uncertainties in strength caused by the defects.

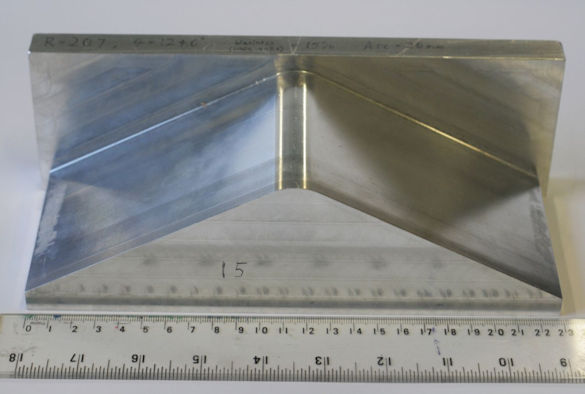

Recreating fibre-waviness defects has been difficult to achieve within laboratories , as they typically only form in large components with curved shapes. However, Liverpool researchers used an innovative manufacturing technique to create defective specimens. These were then used to develop a new method for detecting waviness based on how they cause the material to deform.

The effect of the defects on the strength of the composite material was also measured, giving researchers new insight into how fibre-waviness reduces the strength of aircraft structures.

Liverpool engineer, Dr William Christian, who conducted the research as part of his PhD project, said: “This research has important implications for aircraft manufacturing. By creating representative defects in the lab researchers can develop new methods to locate defects in structures and understand how those defects reduce material strength.

“With greater knowledge of the defect mechanics, lighter aircraft could be developed leading to lower emissions. “

The research paper `An Experimental Study on the Manufacture and Characterisation of In-plane Fibre-waviness Defects in Composites’ is published in the Royal Society journal Open Science.

The work was conducted in the Structural Materials and Mechanics lab in the University’s School of Engineering.

It formed part of a PhD research project looking at how optical measurements of structural deformations can be used to predict the strength of those structures. It was funded by an EPSRC CASE award sponsored by Airbus.